In today’s world, which is often one of complexity and uncertainty, it can be hard for a business to get a clear view of how to achieve optimum performance in an ever-changing market. At the same time, however, organisations have an unprecedented ability to monitor and measure every aspect of their activity.

Nowhere are these challenges and opportunities felt more keenly than in the manufacturing sector. The shop floor is a constant source of valuable data, with every process monitored in detail.

Access deeper industry intelligence

Experience unmatched clarity with a single platform that combines unique data, AI, and human expertise.

Manufacturers, especially in the age of Industry 4.0, have all the data they need to deal with a volatile and complicated marketplace, but they often do not know how to use it. All too often different data streams are housed in separate systems, unable to reveal their true value. That problem was thrown into sharp relief in 2020, as the Covid-19 pandemic forced every industry to reconfigure its working practices and adopt digital technologies.

“The pandemic has been a massive accelerator of digital transformation and the adoption of our Amaze tools, which help companies migrate data and applications to the cloud,” says Kamal Maggon, SVP, manufacturing & consumer at Hexaware. “The speed with which companies want to realise the benefits of the cloud has increased dramatically, and there is a desire to quickly improve their understanding of customers’ pain points and act quickly to address them. That is exactly what Amaze helps them to do.”

Automated cloud migration for optimisation

Automate everything, cloudify everything, transform customer experience. That is the motto of Hexaware, and it is a message that has resonated with manufacturing companies, which have ramped up their adoption of the Amaze tools.

Amaze for Data and AI, for example, can take all of a company’s data and move it to the cloud in a highly automated way. Once on the cloud, that data can be cleaned, integrated and managed in such a way as to be readily available, providing meaningful insights and delivering actionable information on how individual manufacturing processes can be made more efficient.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData“Extreme automation leads to immense cost savings compared to manual processes,” says Maggon. “When you can migrate data to the cloud at speed, you greatly reduce human error, and automation is a fundamental part of everything we do.”

Amaze for Applications has also become an essential tool in the manufacturing industry. It is an automated application re-platforming solution, which accelerates the migration of applications to the cloud by identifying the code which needs changing and converting it into cloud-friendly code without disturbing existing functionality. As a result, adoption time is reduced by up to 75% and implementation costs by up to 60%.

“We find that many companies in the manufacturing sector have expanded over the years through acquisitions,” says Sivakumar V, system analyst and data lead at Hexaware. “That means they have acquired many different technology platforms along the way. We can help them rationalise that technology portfolio.”

“One of our clients had acquired many businesses over a 20-year period and, as a result, had a suite of more than 100 applications,” adds Maggon. “It is looking to unravel the spaghetti, so we are doing a detailed assessment of where they want to be in terms of applications and data, and we are looking to help them get rid of their data centre, which would be a big cost saving.”

Amaze tools analyse each application to determine with it needs to be reworked, retired or rehosted.

“In just a few months, we can move everything onto the cloud and remove all of the applications from the data centre, delivering a massive cost saving,” Maggon explains. “Furthermore, the performance of the applications improves once they are on the cloud because the compute time and the data storage capacity is all available on demand. The company is no longer reliant on its own data storage capacity, so there are no chokepoints.”

Making it happen

Hexaware has been working with manufacturing companies across four key verticals – automotive, energy and utilities, heavy industry and EPC, and discrete manufacturing. In each one, it has been delivering efficiency and cost savings.

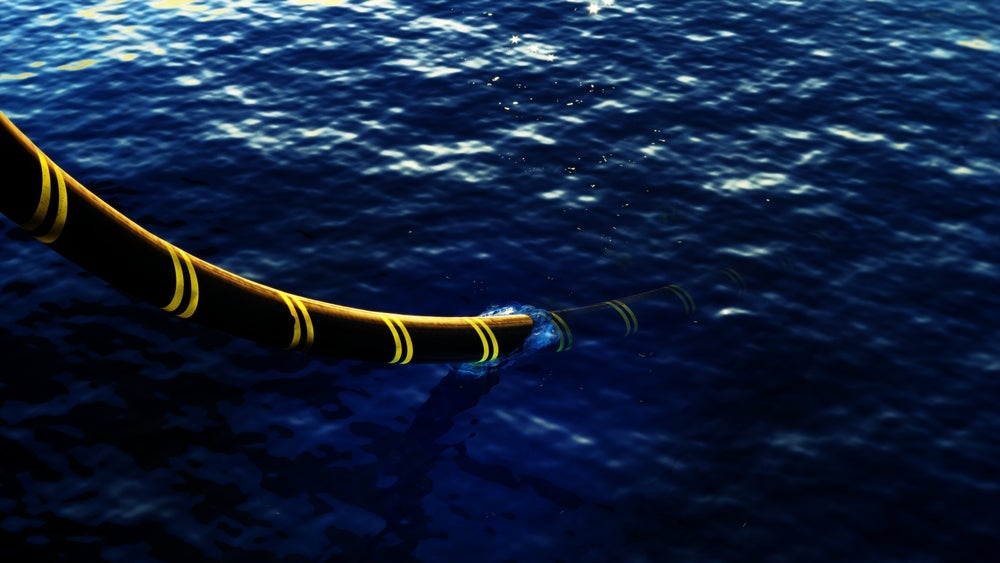

“We are seeing growing demand in EPC and heavy industry,” says Maggon. “Imagine an offshore oil rig or a vessel laying subsea cables. The activity is happening far away from the office where decisions are being made, but those decisions need to be made quickly, based on real-time data. That is where the value of the cloud comes in, and it is why large manufacturing industries are picking up on the benefits of technology transition.”

Hexaware’s constant desire to innovate and its ability to execute cloud migration, along with its willingness to listen closely to its customers’ specific needs, are making real change happen in the manufacturing sector, and the cloud is where the industry’s future lies.