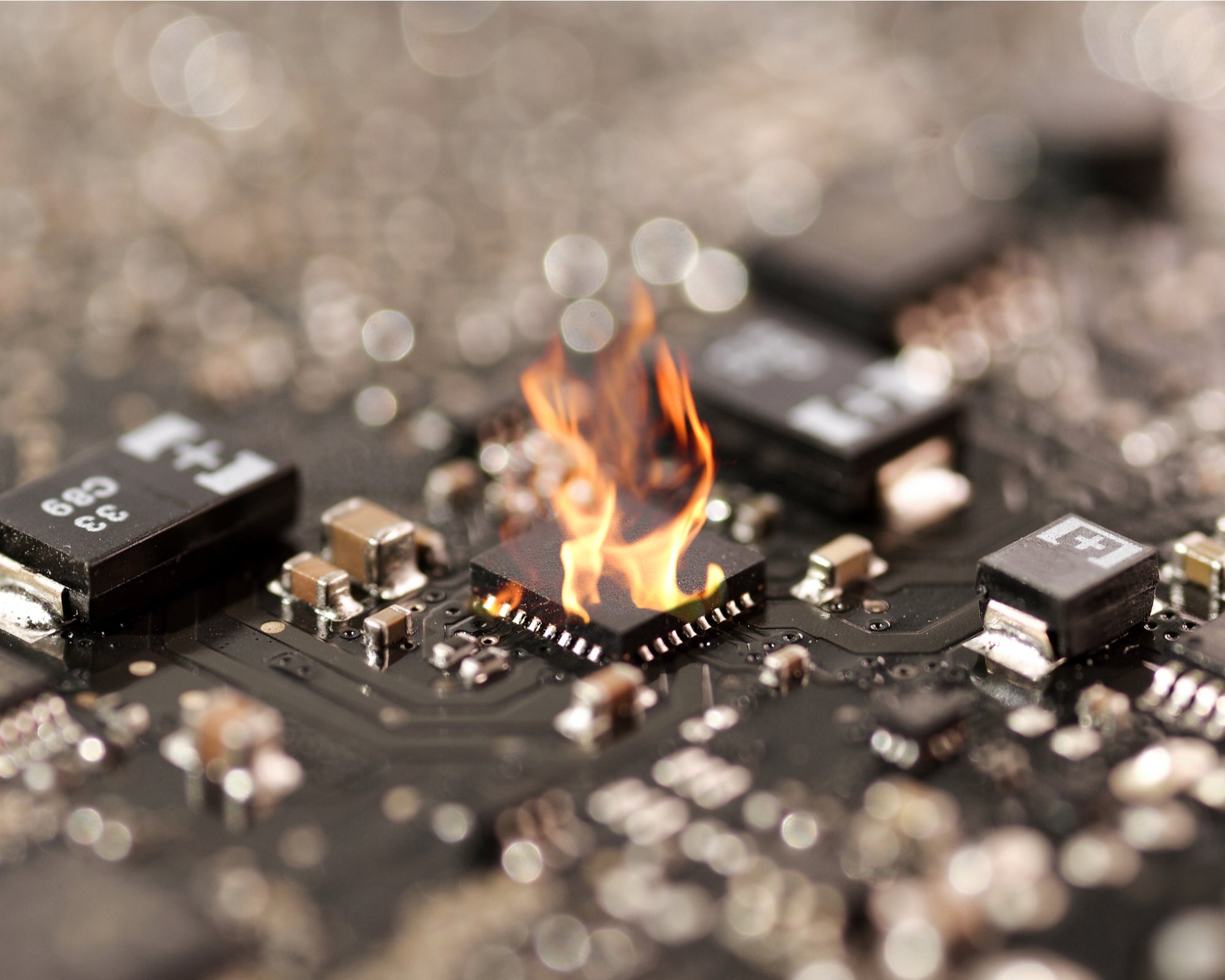

A fire at a semiconductor supplier’s factory in Japan has worsened the global chip shortage. Renesas Electronics said production at its fire-ravaged plant may halt for up to a month.

The semiconductors manufactured at the Naka Factory in Hitachinaka are intended for automotive applications, such as engine management. Automakers have already been struggling to source vital semiconductors after a perfect storm of Covid-19, severe weather and geopolitical tensions meant soaring demand outpaced shrinking supply.

Access deeper industry intelligence

Experience unmatched clarity with a single platform that combines unique data, AI, and human expertise.

On Friday at 2:47 am local time a fire swept through the first floor of the N3 Building at the Naka Factory. Firefighters put out the blaze at 8:12 am. There were no casualties. Renesas Electronics Corporation said there was no damage to the building, but the fire did damage factory equipment, water supply and the air conditioning system.

Production at the N3 building has been halted while investigations and repairs take place. The downtime will affect Renesas’ 300-millimetre chip line. The chipmaker said 11 machines were damaged by the fire, around 2% of all manufacturing equipment in the N3 Building.

“We would like to give our sincerest apologies to neighbouring residents, customers, partner companies, relevant authorities and all those involved, for the trouble the fire caused,” said Hidetoshi Shibata, president and CEO of Renesas. “In addition, we would like to express our gratitude for the fire department and those who partook in the extinguishing of the fire.”

The Japanese firm said shutting down the plant would cost it approximately ¥17bn ($156.3m) per month. But for the wider chip industry, the fallout will be acutely felt.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalData“Although approximately two-thirds of the products manufactured within N3 Building can be alternatively produced in-house or in foundries, due to the recent increase in demand for semiconductors, the situation does not allow for all products to be immediately produced alternatively,” Renesas said in a statement.

In the past few months a slew of car manufacturers including Ford, Volkswagen, General Motors, Toyota and Honda have paused production because they were unable to source the chips needed to manufacture their vehicles.

Slumping car sales during the early days of the Covid-19 pandemic caused many automakers to cancel semiconductor orders. Chip suppliers subsequently switched manufacturing capacity to the consumer electronics market, which by contrast was booming due to a stay-at-home tech boom in devices such as games consoles and laptops.

When car sales picked up again towards the end of 2020, chip manufacturers were unable to meet the increase in demand.

Then, severe weather forced the closure of Samsung Electronics’ foundry in Texas, US, last month – further squeezing global chip supply.

Some automakers, such as Ford, have opted to build vehicles with some chips missing and add them when supply picks up again.

On Saturday Qualcomm CEO Steve Mollenkopf said he is “seeing improvement” in efforts to ease the global chip shortage.

“There’s an ability for the market to respond more quickly to some of the older nodes than the newer nodes, so depending on the product, you may be in a position to get some improvement,” Mollenkopf said, speaking via videolink at the China Development Forum in Beijing.

However, investors appeared to take a gloomier view as shares in Honda Motor fell by 3.2%, Nissan Motor by 2.8% and Toyota Motor by 2.4% on Monday.

Read more: Goodbye Mr Chips: Carmakers lose supply amid global semiconductor shortage