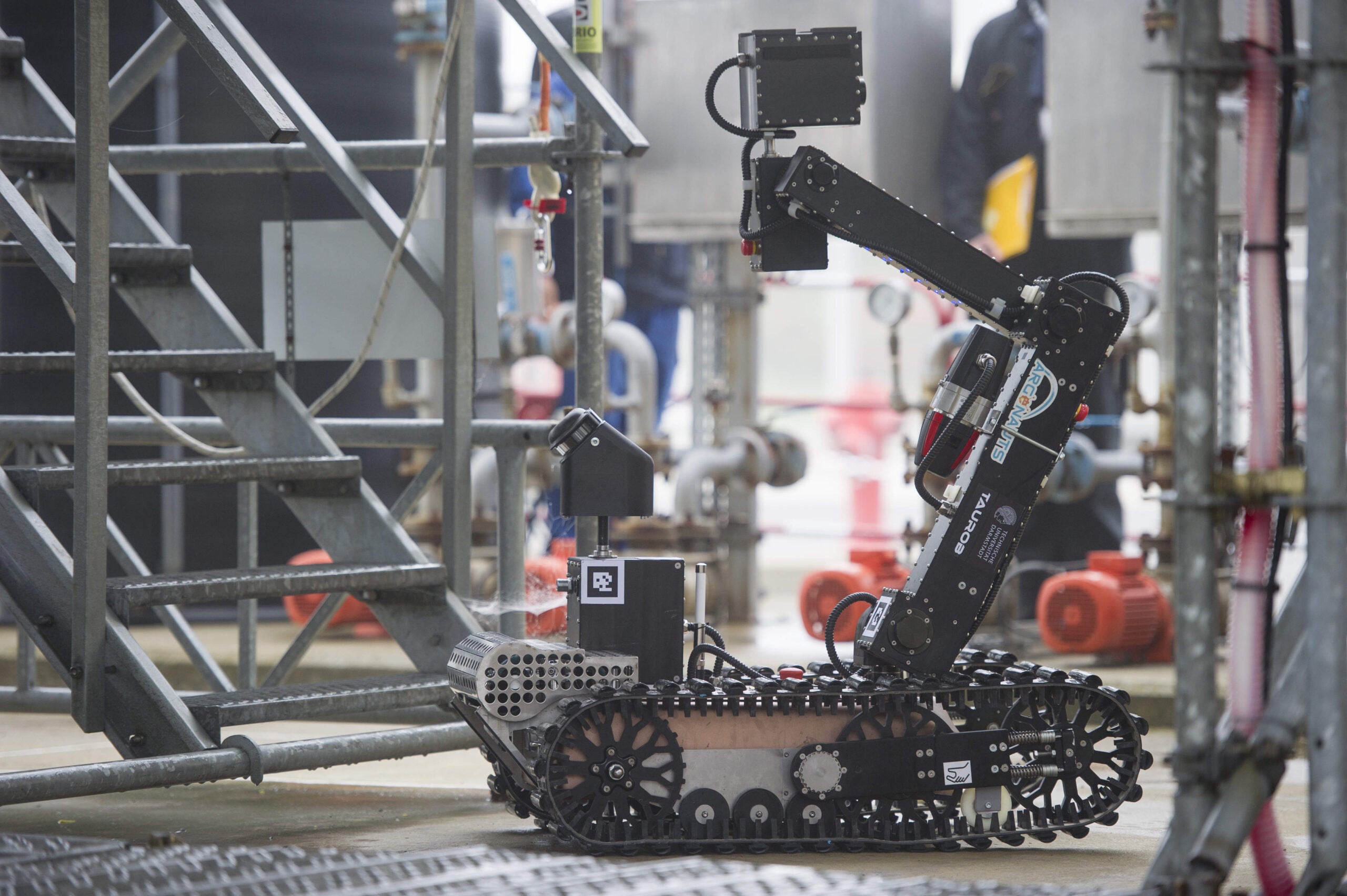

French offshore giant Total E&P has announced that it is developing the first ever autonomous surface robot for the oil and gas industry. The autonomous robot will be used to boost safety on oil rigs and similar offshore structures.

It is the result of Total’s ARGOS (Autonomous Robots for Gas and Oil Sites) challenge, a competition to design and develop a prototype autonomous surface robot. The resulting robot will be able to carry out inspections, read and record measurements and detect anomalies on board oil and gas installations autonomously.

Designed to operate in potentially explosive atmospheres, the autonomous robot can operate in environments that are dangerous to humans, and continue working in emergency situations.

The robot will be tested on Total’s gas treatment plant on the Shetland Islands at the end of 2019 and the company hopes that similar robots will be rolled out throughout the world from 2020 onwards.

Head of Total E&P’s R&D department Daniel Plathey said:

“This robot increases the security of operations and improves the comfort of teams performing them: they’re released from having to perform demanding tasks and routine inspections, so they can focus on tasks with greater added value. It improves our operational performance, optimising the way in which onshore and offshore facilities are managed, as well as reducing their costs.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalData“Conducted as an open innovation project, it emphasises the maturity of Total’s R&D initiatives and establishes the group as a world leader in autonomous terrestrial robotics for oil and gas activities.”

Robots and drones are impacting the offshore oil market

Although automation has been used on oil and gas installations since the 1970s, robotics is still a fairly new phenomenon in the industry, with the adoption of such technology slow when compared with other industries such as manufacturing.

However, the industry is now making progress, with the inspection robots market expected to grow at a CAGR of 17.3% between 2018 and 2026, according to a report by Credence Research.

Several energy companies are now investing in robotics. Last month, BP trialled the use of a magnetic crawler known as MaggHD, along with drones, to conduct inspections of its Thunder Horse platform in the Gulf of Mexico. Previously, tasks such as this would have been timely and dangerous; carried out by rope access technicians.

Technology company Eelume is developing a robotic ‘snake’ that can ‘swim’ through the water using its slender and flexible body to inspect and repair underwater infrastructure.

However, both of these are remote controlled, whereas Total’s robot will work autonomously.

In 2017, The Edinburgh Centre for Robotics and the UK Industrial Strategy Challenge Fund launched a £19m initiative to develop AI for the inspection, maintenance and repair of offshore oil and gas and renewable sector installations, suggesting other autonomous technologies are on their way.

Automation to improve offshore safety

The onshore or offshore oil industry is notoriously dangerous, with the National Institute for Occupational Safety estimating that workers in the oil and gas industry are six times more likely to die on the job than the average worker in the US. Automation therefore has the potential to greatly benefit the industry by reducing the need for workers to conduct dangerous inspections and maintenance.

Asset integrity solution centre manager at the Oil and Gas Technology Centre Rebecca Allison believes that technologies such as Total’s autonomous robot have the potential to free up workers for higher skilled jobs by taking over more tedious or dangerous tasks:

“Robotics has the potential to transform the offshore oil and gas industry. We have countless repetitive, dirty and potentially dangerous tasks carried out every day. Integrating robots for these tasks will help upskill our workforce and improve the quality of the jobs. Projects like this will help inspire and attract the next generation oil and gas workforce.”

The oil industry is facing a growing labour and skill shortage since the oil price collapse of 2014, with the North Sea oil and gas industry needing to recruit and train an estimated 125,000 workers in the next ten years to keep up with demand. Naturally, automation is a way to remedy this, through improving efficiency and lessening the need to recruit for often hard-to-fill jobs on board oil rigs.

Autonomous robot deployment and offshore job loss concerns

The common concern over whether automation will lead to job loss remains, but with new technology comes the need for workers to maintain and programme robotics.

Vice-president of operational excellence for Equinor (formerly Statoil) Jim Claunch told E&P Magazine that automation could actually create jobs:

“The more jewellery we put on the wells and pads out there, we’re going to have people that are making sure the sensors are working and the communication is working — the whole nine yards. We are also looking at broader skillsets for those people.”

With volatile prices and cuts in investments, robotics could enable oil and gas companies to continue operating efficiently.

Next-generation conventionals manager for Total SA Jean-Michel Munoz believes automation could transform the oil industry:

“Surface robotics has the potential to completely change the way we operate and design facilities in the future. Implementing this technology on our sites will bring benefits in terms of operation safety and cost optimisation. This development of a fully autonomous robot for operator rounds and anomaly detection is the first step in implementing robotics solutions at industrial scale.”