The technology industry continues to be a hotbed of patent innovation. Activity is driven by the need for more efficient and cost-effective maintenance processes in industries such as manufacturing, energy, and transportation, and growing importance of technologies such as artificial intelligence (AI)-powered diagnostics and predictive maintenance algorithms, which enable robots to autonomously identify and address issues. In the last three years alone, there have been over 1.5 million patents filed and granted in the technology industry, according to GlobalData’s report on Robotics in technology: robotic maintenance. Buy the report here.

Access deeper industry intelligence

Experience unmatched clarity with a single platform that combines unique data, AI, and human expertise.

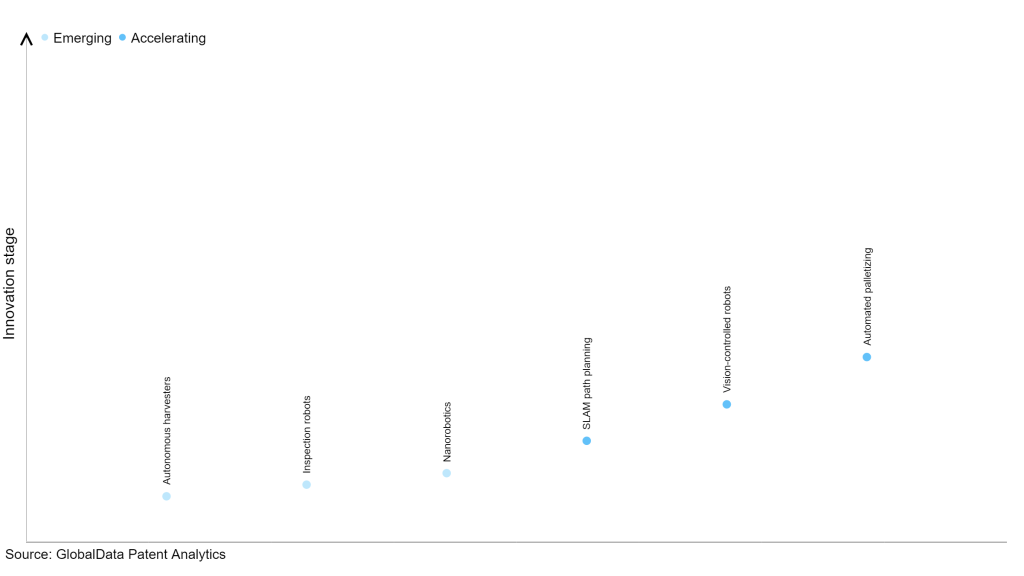

However, not all innovations are equal and nor do they follow a constant upward trend. Instead, their evolution takes the form of an S-shaped curve that reflects their typical lifecycle from early emergence to accelerating adoption, before finally stabilizing and reaching maturity.

Identifying where a particular innovation is on this journey, especially those that are in the emerging and accelerating stages, is essential for understanding their current level of adoption and the likely future trajectory and impact they will have.

185+ innovations will shape the technology industry

According to GlobalData’s Technology Foresights, which plots the S-curve for the technology industry using innovation intensity models built on over 1.6 million patents, there are 185+ innovation areas that will shape the future of the industry.

Within the emerging innovation stage, autonomous harvesters, inspection robots and nanorobotics are disruptive technologies that are in the early stages of application and should be tracked closely. SLAM path planning, vision-controlled robots, and automated palletizing are some of the accelerating innovation areas, where adoption has been steadily increasing.

Innovation S-curve for robotics in the technology industry

Robotic maintenance is a key innovation area in robotics

Robotic maintenance encompasses the utilization of robots or automated systems for executing maintenance operations across diverse industries. Equipped with specialized tools and sensors, these robots conduct tasks such as inspection, repair, and equipment replacement. They are engineered to function autonomously or under human supervision, reducing the need for extensive human involvement and enhancing the effectiveness of maintenance procedures.

GlobalData’s analysis also uncovers the companies at the forefront of each innovation area and assesses the potential reach and impact of their patenting activity across different applications and geographies. According to GlobalData, there are 405+ companies, spanning technology vendors, established technology companies, and up-and-coming start-ups engaged in the development and application of robotic maintenance.

Key players in robotic maintenance – a disruptive innovation in the technology industry

‘Application diversity’ measures the number of applications identified for each patent. It broadly splits companies into either ‘niche’ or ‘diversified’ innovators.

‘Geographic reach’ refers to the number of countries each patent is registered in. It reflects the breadth of geographic application intended, ranging from ‘global’ to ‘local’.

Among the companies innovating in robotic maintenance, Boeing is one of the leading patents filers. The company’s patent describes a method for placing a piece of composite material onto a substrate. The piece of the composite material is compacted against the substrate, while also holding the piece of composite material against the substrate using the end effector. Other prominent patent filers in the space include Fanuc and Kobe Steel.

In terms of application diversity, Boeing held the top position, while Fanuc and Gecko Robotics stood in the second and third positions, respectively. By means of geographical reach, Gecko Robotics leads the pack, followed by SoftBank and RoboTire.

Robotic maintenance plays a pivotal role in revolutionizing industrial operations by introducing precision, efficiency, and cost-effectiveness in maintenance activities. These robots are equipped with advanced sensors and tools, allowing them to autonomously inspect, repair, and replace machinery, leading to reduced downtime, improved safety, and enhanced overall productivity.

To further understand the key themes and technologies disrupting the technology industry, access GlobalData’s latest thematic research report on Robotics.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.