The technology industry continues to be a hotbed of innovation, with activity driven by the increasing complexity of semiconductor designs, the need for high-quality manufacturing, and the demand for faster inspection processes. Also, growing importance of technologies such as machine learning algorithms, computer vision, and pattern recognition are driving the market. In the last three years alone, there have been over 3.6 million patents filed and granted in the technology industry, according to GlobalData’s report on Innovation in Artificial Intelligence: Wafer defect inspection system. Buy the report here.

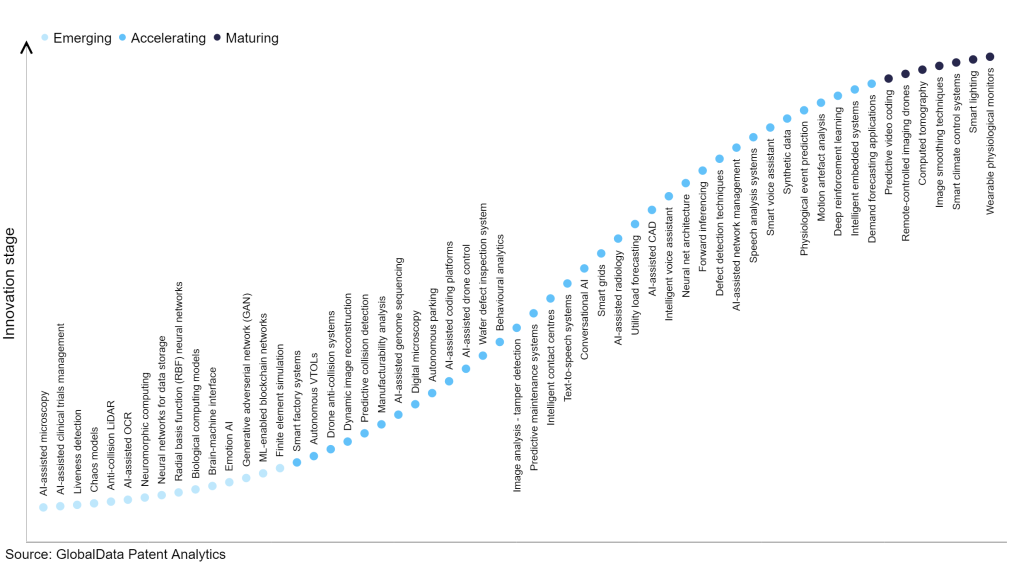

However, not all innovations are equal and nor do they follow a constant upward trend. Instead, their evolution takes the form of an S-shaped curve that reflects their typical lifecycle from early emergence to accelerating adoption, before finally stabilising and reaching maturity.

Identifying where a particular innovation is on this journey, especially those that are in the emerging and accelerating stages, is essential for understanding their current level of adoption and the likely future trajectory and impact they will have.

300+ innovations will shape the technology industry

According to GlobalData’s Technology Foresights, which plots the S-curve for the technology industry using innovation intensity models built on over 2.5 million patents, there are 300+ innovation areas that will shape the future of the industry.

Within the emerging innovation stage, finite element simulation, generative adversarial network (GAN), and ML-enabled blockchain networks are disruptive technologies that are in the early stages of application and should be tracked closely. Demand forecasting applications are some of the accelerating innovation areas, where adoption has been steadily increasing. Among maturing innovation areas are smart lighting and wearable physiological monitors, which are now well established in the industry.

Innovation S-curve for artificial intelligence in the technology industry

Wafer defect inspection system is a key innovation area in artificial intelligence

A wafer defect inspection system is a system that utilizes automated optical inspection technology to detect, identify, and classify defects on semiconductor wafers. It can be used to detect a wide range of defects such as particle contamination, surface damage, scratches, and pinholes. This system provides a comprehensive view of the wafer's surface, enabling manufacturers to quickly identify and respond to process issues that could otherwise lead to costly product failures.

GlobalData’s analysis also uncovers the companies at the forefront of each innovation area and assesses the potential reach and impact of their patenting activity across different applications and geographies. According to GlobalData, there are 40+ companies, spanning technology vendors, established technology companies, and up-and-coming start-ups engaged in the development and application of wafer defect inspection system.

Key players in wafer defect inspection system – a disruptive innovation in the technology industry

‘Application diversity’ measures the number of different applications identified for each relevant patent and broadly splits companies into either ‘niche’ or ‘diversified’ innovators.

‘Geographic reach’ refers to the number of different countries each relevant patent is registered in and reflects the breadth of geographic application intended, ranging from ‘global’ to ‘local’.

Patent volumes related to wafer defect inspection system

Source: GlobalData Patent Analytics

KLA is a leading patent filer in the wafer defect inspection system space. One of the company's patents outlines a system for determining characteristics of a pattern on a wafer specimen. The system includes an output acquisition subsystem and a computer subsystem. The output acquisition subsystem directs energy to the specimen while a detector generates output. The computer subsystem acquires and selects instances of the pattern's output based on characteristics determined by an inspection system. By utilising the higher-resolution output from the output acquisition subsystem, the system checks the characteristics of the pattern of interest.

Other prominent patent filers in the space include Toshiba and Hitachi.

By geographic reach, Fogale Nanotech leads the pack, followed by DAIHEN and Screen Holdings. In terms of application diversity, Kulicke & Soffa Industries holds the top position, followed by Fogale Nanotech and Rambus.

Artificial intelligence (AI) innovation in wafer defect inspection systems refers to the integration of AI technologies to enhance the accuracy and efficiency of detecting defects in semiconductor wafers. Major technologies involved in AI-based wafer defect inspection systems include machine learning algorithms, computer vision, and pattern recognition, which enable automated defect detection, classification, and analysis, leading to improved productivity and yield in semiconductor manufacturing.

To further understand how artificial intelligence is disrupting the technology industry, access GlobalData’s latest thematic research report on Artificial Intelligence (AI) – Thematic Intelligence.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.