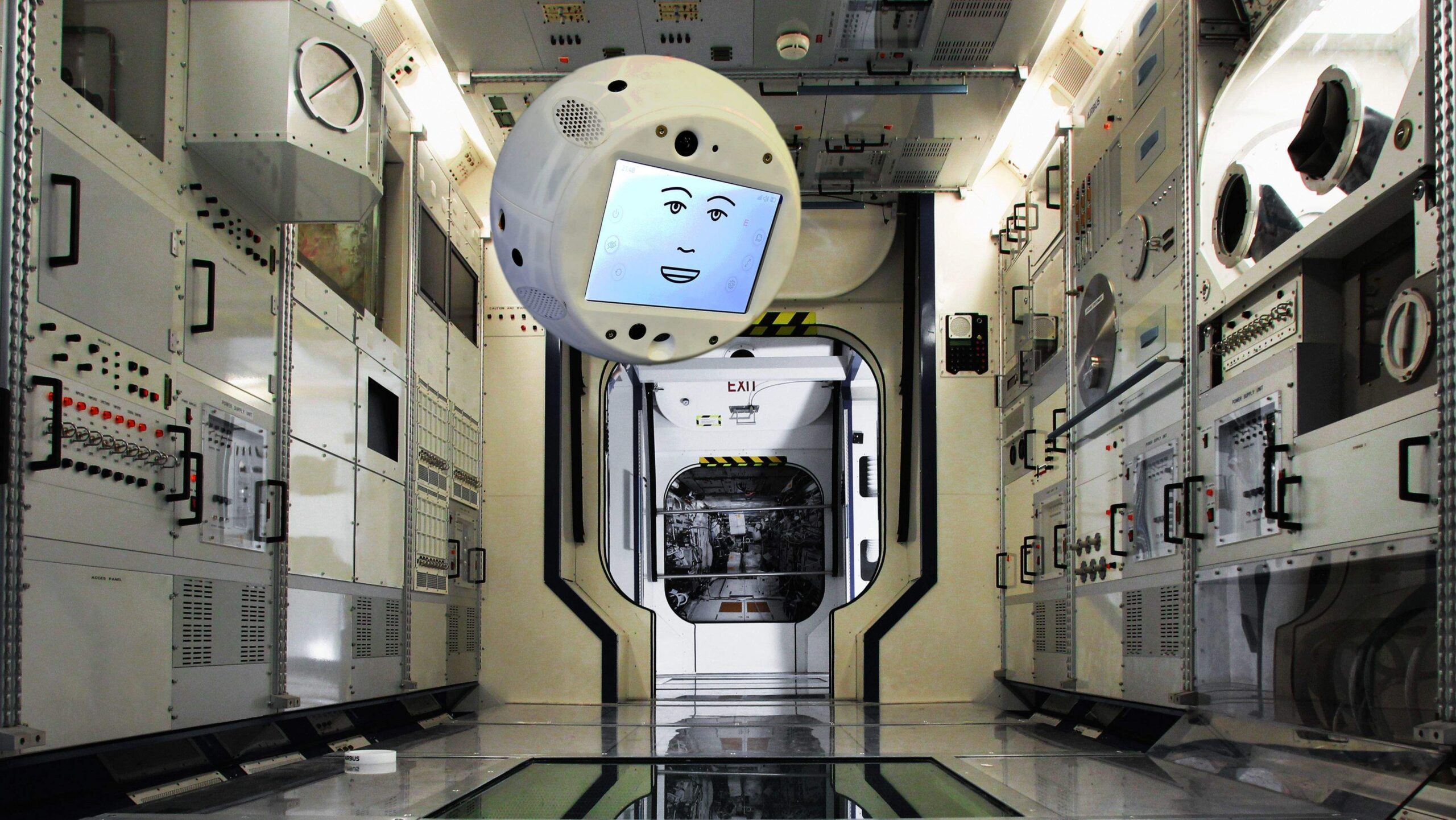

Meet CIMON (or Crew Interactive Mobile Companion) ─ the first space-flying artificial intelligence robot to join astronauts on the International Space Station (ISS).

Reassuringly less sinister than 2001: A Space Odyssey’s nightmarish HAL-9000, CIMON is due to travel to the ISS on the SpaceX CRS-15 mission later this month to join a team of astronauts who set off on the Soyuz MS-09 rocket that launched yesterday.

Developed by Space Administration at the German Aerospace Centre in collaboration with Airbus, CIMON is a collaborative robot, meaning it is designed to work alongside astronauts in performing routine tasks.

CIMON is able to interact with crew members via facial expressions and voices, and due to its ‘neural’ AI network, can learn and offer solutions to issues. In practical terms, CIMON has been designed to assist in increasing efficiency, facilitate mission success and improve security, but is also able to play music, help reduce stress and even tell jokes.

Head of microgravity payloads at Airbus Manfred Jaumann said:

“We are the first company in Europe to carry a free flyer, a kind of flying brain, to the ISS and to develop artificial intelligence for the crew on-board the space station.”

Although currently only able to perform simple tasks, researchers plan to use CIMON to examine psychological side-effects that can develop over long periods of time in small teams during long-term missions to the Moon or Mars.

In such missions, social ‘interactions’ between crew members and collaborative robots may play an important role in their success.

What is a collaborative robot?

A collaborative robot ─ or cobot ─ is a robot intended to physically interact with humans in a shared workspace. Rather than working alone, cobots are designed to function like an AI ‘colleague’, and can interact directly and safely with humans.

Lightweight, easy to deploy and cheaper than industrial robots, cobots can complete mundane or dangerous tasks, leaving humans to complete duties robots are unable to do.

Unlike stationary industrial robots that often require large safety enclosures, cobots are able to move around an environment without posing a risk to humans, meaning they can perform a more diverse set of tasks.

With the cheapest cobot costing just under £5,000, as well as reducing human idle time by 85% according to an MIT study, introducing cobots to the workforce may to be an attractive prospect in terms of cost-saving and productivity for many employers.

Cobots are already a common feature of some sectors

Over the past decade, cobots have been making their way into a variety of sectors.

In March, Amazon opened a robotics fulfilment centre in Illinois, where 2,000 employees work alongside Kiva robots that are able to move boxes and deliver items to their human colleagues.

Earlier this year, online supermarket Ocado announced that it intends to add ARMAR-6 cobots to its workforce to assist technicians in warehouses in tasks that require greater precision or physical strength.

However, use of cobots is not just limited to industrial automation, and has opened up the possibility of incorporating robotics into other sectors. In 2016, researchers at the University of Birmingham developed a robot office manager called Betty. Put to work in an office in Milton Keynes, Betty’s job included counting the number of employees and monitoring the office environment.

A restaurant in California recently made the news after installing a robot that could flip burgers using a spatula-fitted arm. Unfortunately the cobot, known as Flippy, was taken offline after just one day on the job due to being too slow.

What will cobots mean for the workforce?

Predicted to be worth more than $4bn by 2023, the cobot market is growing. There is little debate that such technology is a disruptive innovation for production and manufacturing, but what will this mean for the human workforce?

Opinion is split on the extent to which cobots will impact the workplace, with some remaining sceptical. Professor of mechanical engineering at Northwestern University Michael Peshkin believes that there are still significant limitations of what cobots are capable of.

He told IndustryWeek: “A human, for example, could very easily notice that some out-of-position wires are interfering in an assembly, and brush them away to continue the work. A machine, on the other hand, would have great difficulty even recognising the wires, and just as much difficulty in pushing them out of the way. Unlike humans, robots can generally only cope with problems that were predicted for them.”

Cobots currently make up a small proportion of robots being used. According to Deloitte, traditional industrial robots are still the biggest segment of the robotics market, while only 9,000 of the 300,000 industrial robots manufactured last year were cobots.

However, cobots may be the answer to the dilemma of whether AI will leave many human employees jobless, which provokes a reluctance from many workers to embrace such technology.

While cobots are able to take on dull and dangerous tasks, higher-level tasks such as programming and problem solving still need a human touch. As a result, the use of cobots could mean that AI plays a complementary role rather than posing a threat.

Some research suggests that cobots could in fact increase the number of job opportunities. According to research conducted by Gartner, AI will eliminate 1.8 million jobs by 2020, but will create 2.3 million positions in the same timeframe.

Director of the MIT Initiative on the Digital Economy Erik Brynjolfsson said:

“Most jobs will be partly affected by machine learning, but there will also be things humans need to do. Instead, the future will likely involve partnerships between humans and machines to more efficiently get work done. Rarely will we completely wipe out entire job categories.”