Since the development of the commercial jet aircraft, little has changed about its fundamental design.

Performance improvements have certainly been made, but the basic tube-and-fixed wing design has remained the same. However, certain designs and technologies may represent the future of commercial travel.

The oblique wing

The idea of an oblique wing design was revived by NASA researcher Robert Jones in the 1950s and his research continued well into the 1990s. The purpose of the design is to allow for optimal fuel efficiency at subsonic and supersonic speeds by pivoting the aircraft’s wing on a central axis from a perpendicular to an oblique angle, respectively. The aircraft’s wing would be fixed to the top of the fuselage rather than into the sides to allow for this pivot. Being able to pivot the wing so that one tip is swept forward while the other is swept to the rear reduces drag at high speeds while retaining efficiency at low speeds with a perpendicular wing orientation.

Returning to an age of supersonic commercial flight has been an engineering challenge since the retirement of the Concorde program in 2003. Even aside from a fatal crash of a Concorde aircraft in 2001, the program experienced several issues: it was over-budget, exceptionally fuel inefficient at low speeds, and was limited to transoceanic routes because of the sonic booms created by its speed.

While an oblique wing design wouldn’t prevent sonic booms from happening, the concerns regarding major fuel inefficiency at low speeds and associated environmental impact are mitigated, at least in part. Improving fuel efficiency would also make exclusively transoceanic routes more viable and help to reduce travel times. Because of its specialised use cases, an oblique wing design is unlikely to become the ubiquitous standard for commercial aviation design. However, it may facilitate a return to the much-desired supersonic transatlantic and transpacific flight.

The blended wing

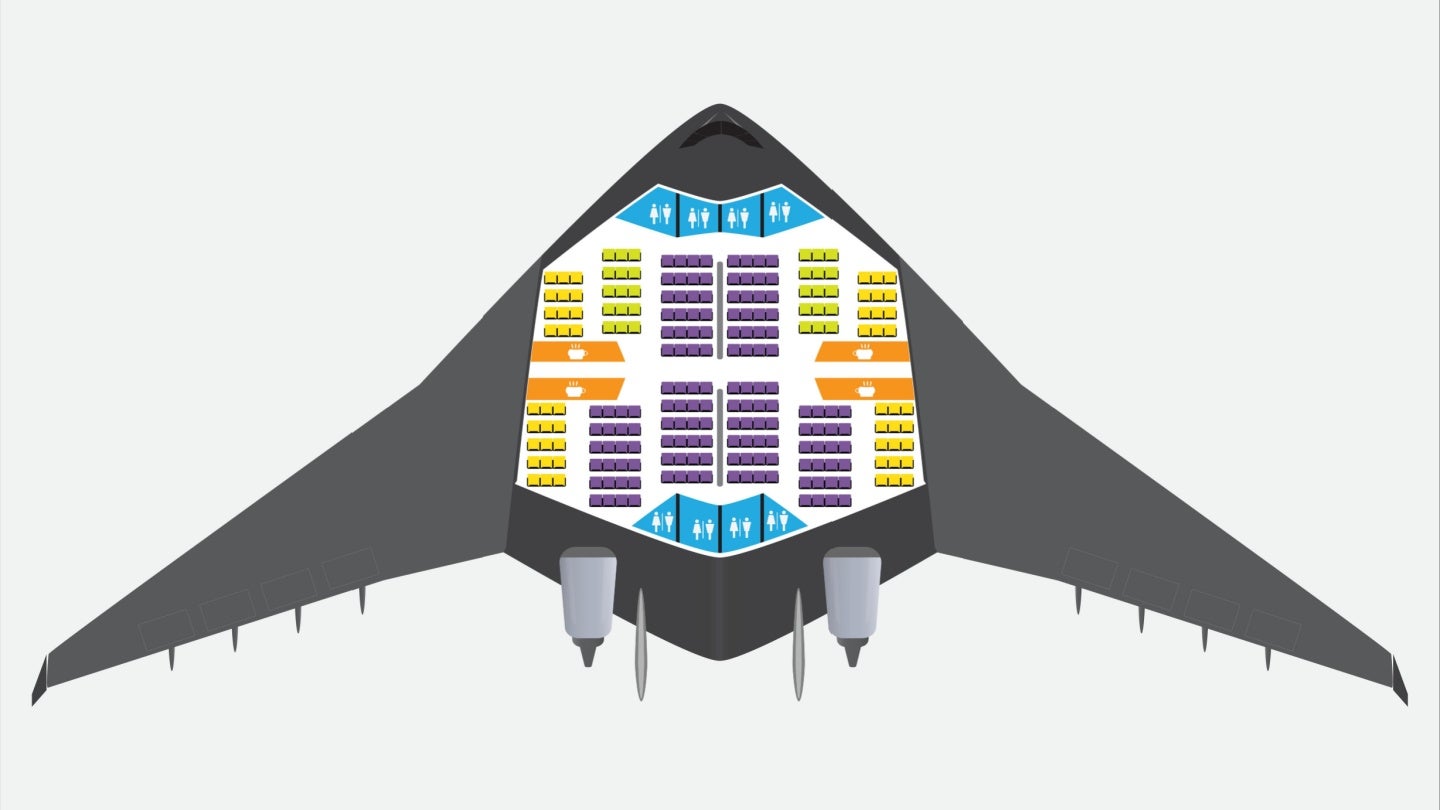

While the wheel doesn’t need to be reinvented, companies like JetZero think that the commercial airliner does need to be. Their Blended Wing design purports to have several advantages over traditional tube-and-fixed wing designs. The main features are a shorter and wider fuselage that blends into the aircraft’s wings, creating a seamless transition between the body and extremities. The design’s dimensions are intended to improve aerodynamic efficiency, lift, and fuel efficiency, and decrease drag and weight.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataA crucial element of JetZero’s design is its compatibility with existing aviation infrastructure. Its adherence to current norms means that no changes to how passengers access the aircraft—be that through a covered walkway or stairs from the runway—are necessary. This would help make the transition from existing fleets to updated ones with a blended wing design as close to seamless as possible.

Sustainable commercial aviation fuels

Perhaps most important is the blended wing design’s compatibility with sustainable aviation fuels (SAFs). SAFs are themselves already compatible with existing aviation infrastructure, using the same storage and piping as traditional fuels. Currently, SAFs lack the energy density to completely replace traditional fuels while retaining performance.

However, due to the improvements to aerodynamics and fuel efficiency made by the blended wing design, this would be much less of a problem. Adopting such designs by commercial aviation would go a long way to reducing the carbon emissions of the industry and may accelerate the achievement of net zero targets.