Materialise, a 3D printing company, has launched a personalised temporomandibular joint (TMJ) treatment, Total Arthroplasty System.

The system, which comprises implants, guides, and digital planning, is designed to treat patients for total temporomandibular joint (TMJ) arthroplasty.

The TMJ, the joint where the skull and jawbone meet, plays a crucial role in the opening and closing of the jaw.

Founded in 1990, Materialise is headquartered in Leuven, Belgium, and specialises the 3D printing sector. The company went public in 2014, the same year it acquired OrthoView, orthopaedic planning software and established a new office in China, namely Materialise Shanghai.

According to a recent case study by Materalise, patients who received the personalised TMJ prosthesis experienced improvements in their quality of life, pain levels, and eating ability compared to pre-surgery.

The study reported accurate implant placement in 97% of cases, with clinicians attesting to a 100% success rate one year post-surgery.

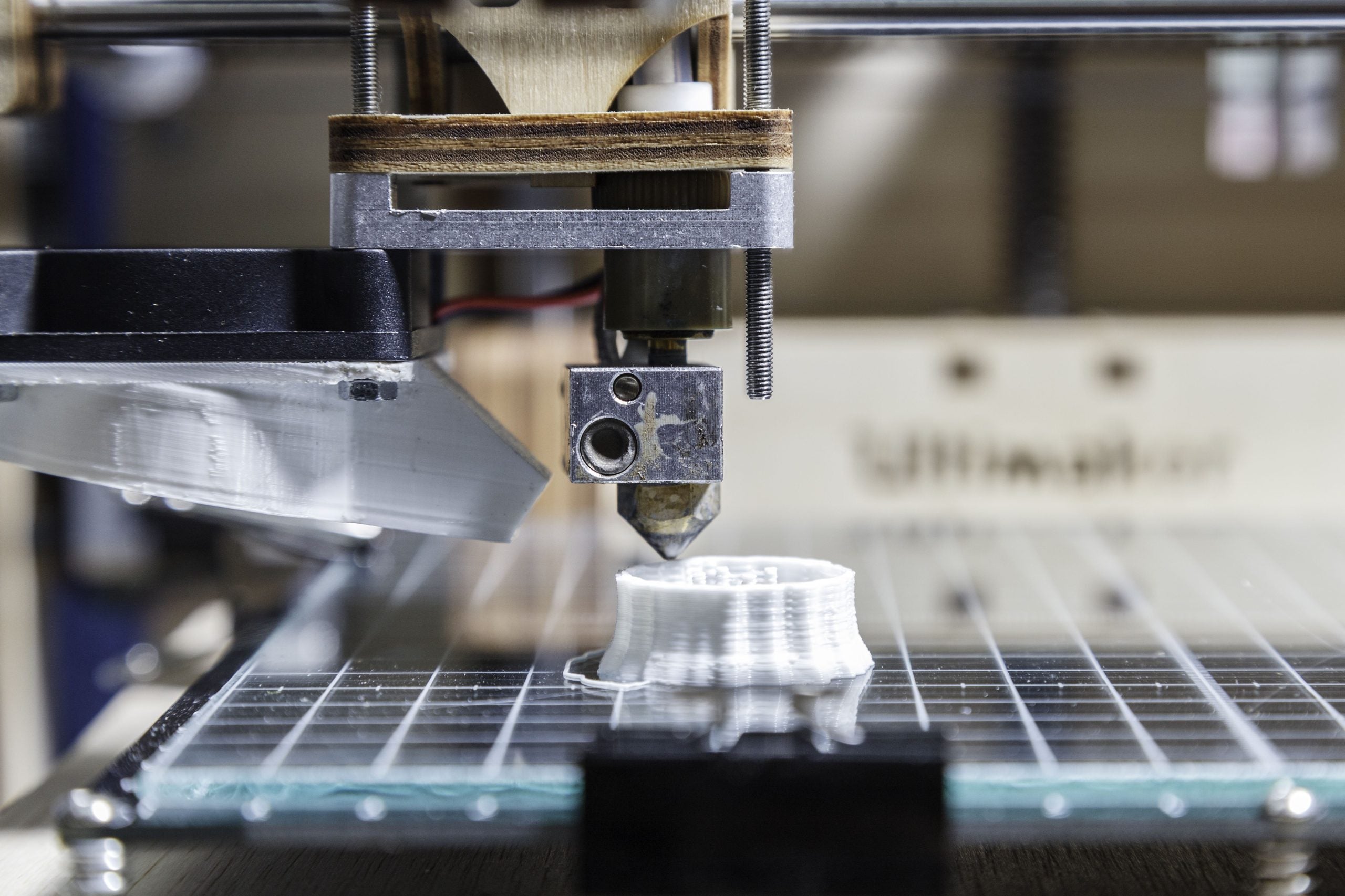

In recent years, 3D printing has had a significant impact on the creation of prosthetics by making personalised prosthetics available to patients for a lower cost and shorter timeframe.

The technology is also useful for clinicians, who can use models in pre-operative planning and explaining procedures or diagnoses to patients.

Martijn Orye, market specialist at facial surgery global networking organisation, CMF, underscored the impact of personalised treatments on complex cases like TMJ replacements, stating, “Personalised solutions are becoming the primary choice for more challenging or complex cases such as TMJ replacements.”

The process begins with a patient’s CT scan and dental information. Through an interactive online session, a Materialise clinical engineer works with a physician to plan surgery and the device’s design.

Once finalised, Materialise manufactures the TMJ implant, providing it to the physician for surgery.

Materialise recently established a medical 3D printing facility in Plymouth, Michigan, in August 2023, specialising in titanium implants for facial reconstructive surgery.