3D printing will be a $32bn industry by 2025, rising to over $60bn by 2030, according to estimates from analytics firm GlobalData. The CAGR between 2018 and 2025 will be 16%, with software growing slightly faster than hardware, materials and services.

How much healthcare will contribute to this growth remains to be seen. In 2018, healthcare represented only 10% of online printing demand. In contrast, the industrial and electrical sectors represented approximately 50%.

But changing trends may see a necessity for more 3D printing in hospitals and places of care. As a new GlobalData report on 3D printing in healthcare states, the growing old-age population has driven the demand for donor organs, while regenerative medicine using bioprinted, patient-derived stem cells allows for personalised treatment of certain diseases.

“Use of bioprinted human tissue in drug discovery allows for quicker and more efficient processes, with better outcomes compared to using animal tissue,” say the researchers. “It also removes the need for animal testing, both in drug and cosmetic development.”

3D printing may also revolutionise Big Pharma, with drugs being printed and adapted to specific patient requirements such as age and weight. This could equally save the pharmaceutical industry millions in costs, resources and waste.

It shouldn’t be a surprise to know that the pandemic has played its part in galvanising the technology’s use. The 3D printing community, from major manufacturers to start-ups and individuals, has responded to the Covid crisis by pledging to support the production of vital medical equipment such as ventilators and personal protective equipment (PPE) for hospitals tackling the pandemic.

The medical data

A recent study into the costs versus benefits of introducing 3D printing technology into hospitals has shown that the tech can aid complicated surgeries.

The June study, undertaken by Dr Atanu Chaudhuri, Associate Professor in Technology and Operations Management at Durham University Business School, alongside colleagues at ORT Braude College of Engineering in Israel and the University of Southern Denmark, assessed the effectiveness of 3D printing technologies used in hospitals.

Results show 3D printing to be a key tool in easing both time and financial pressures for hospitals.

“Surgeries with durations of 4-8 hours can be shortened by 1.5-2.5 hours if patient specific instruments are used and 25-30 minutes shorter if only an anatomical model is used to plan the surgery,” Dr Chaudhuri tells Verdict.

“Patient recovery times are also shorter (e.g. a patient is able to walk 1-2 days after surgery compared to 3-4 days before). Moreover, the patient will avoid any post-surgical complications and hence will not need to visit hospital or undergo other kinds of treatment.”

Chaudhuri doesn’t specifically compare success rates, noting that even earlier surgeries had been successful but could have led to post-surgical complications and longer recover time.

“But, there are certain surgeries which were not attempted before, especially for smaller children, which could now be conducted with much more confidence,” he reveals.

Whilst the benefits are clear and compelling, Chaudhuri and his fellow researchers advise caution. They acknowledge that 3D printing is a significant financial investment for hospitals to make, particularly those run by the British NHS already operating under heavy financial pressures, especially in pandemic times.

“Benefits can far outweigh costs both for hospitals as well as for patients,” says Chaudhuri. “But, we must know where to apply it and how to quantify the benefits.”

He also believes 3D printing should be a collaboration between surgeons and engineers, with no one party having an advantage over another through clinical or technical knowledge.

“(One) myth is that ‘Surgeons should not be involved in design or 3D printing.’ But surgeons who are learning how to do segmentation, how to design a surgical guide, will be ahead of others. Eventually many surgeons will like to learn about 3D printing and it will get integrated with the medical curriculum.

“The other myth is ‘Engineers from service providers do not understand clinical requirements well.’

“This may be initially true but many service providers have learnt the clinical aspects by working with many surgeons and hence when they talk to a hospital, which has not applied the technology before, they will already provide valuable experience and guidance, particularly on what is possible and what is not.”

The future of 3D printing in healthcare

Clinical and operational outcomes of using 3D printing in surgeries have been demonstrated. But Chaudhuri sees a need for “systematic studies for which type of surgeries and for which patient characteristics, are the impacts highest?

“For public health systems, such cost-benefits analysis is critical,” he tells Verdict. “For private healthcare, there should be value-for-money for patients.”

Chaudhuri says use of anatomical models will become standard for surgeries. 3D printed surgical guides and implants meanwhile will be used where the benefits are highest followed by advanced 3D printed models for surgical simulations for more complex surgeries.

“3D bio printing i.e. printing of organs is further out in the horizon, but development is happening at a rapid pace.

“Use of virtual and augmented reality in combination with 3D printing has high potential for complex surgeries, which deal with challenges of high visual-spatial complexity and extensive anatomic variation.”

The physician also predicts a strong demand for tailor-made medical implants and surgical instruments to individual patients.

“One of the leading applications of 3D printing in surgeries are in orthopaedics and orthopaedic oncology, especially in complex restructuring operations, followed by cranio-maxillofacial, neurosurgeries and cardiology.

“(But) as I said before, more studies are needed across specialties and for different types of patients.”

The executive view

The future of 3D printing in healthcare will rely on executives as much as acceptance from medical experts. According to the data, it looks as though management is taking note.

In GlobalData’s Emerging Technology Trends Survey 2019 report, 146 medical executives were surveyed across 23 countries. All respondents confirmed some level of engagement with new and emerging technologies.

According to respondents, three-quarters of medical device companies expected 3D printing to disrupt the sector. When asked when they think 3D printing will start having a disruptive influence on the sector, 62% of industry leaders believed the disruption would occur within the next two to three years.

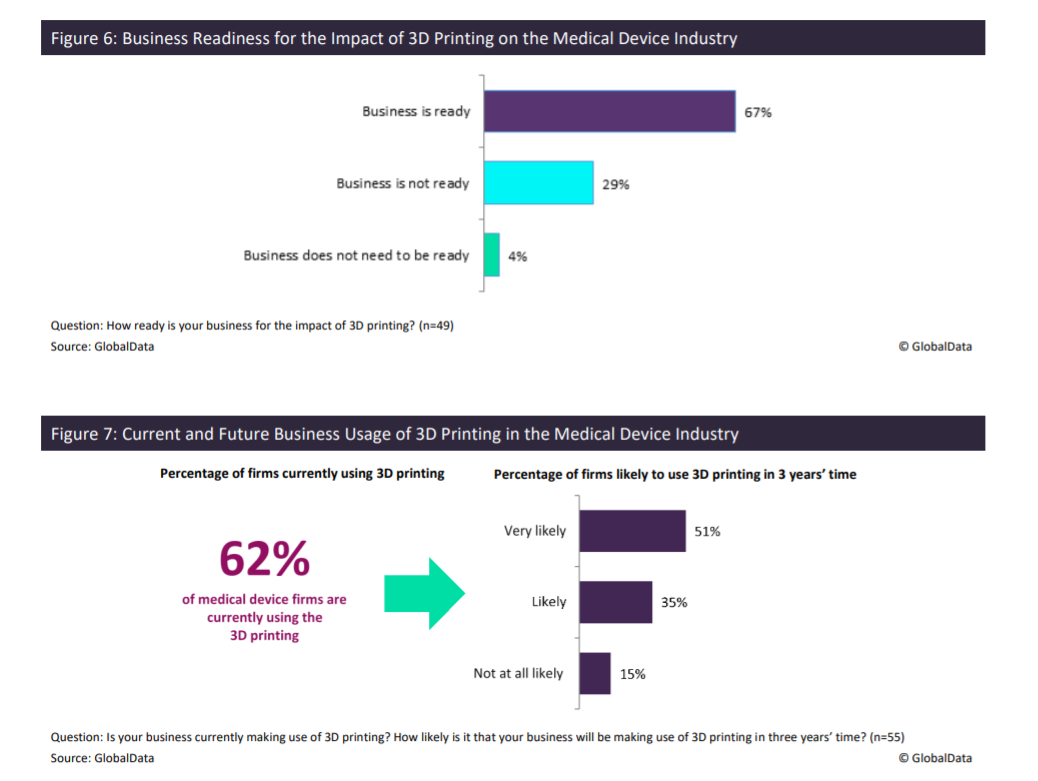

A total of 67% of respondents indicated that their business was ready for the impact 3D printing may bring, while approximately one-third indicated their business is not. Most medical device companies are currently using 3D printing, with only 15% of respondents stating that they were not at all likely to use it within the next three years.

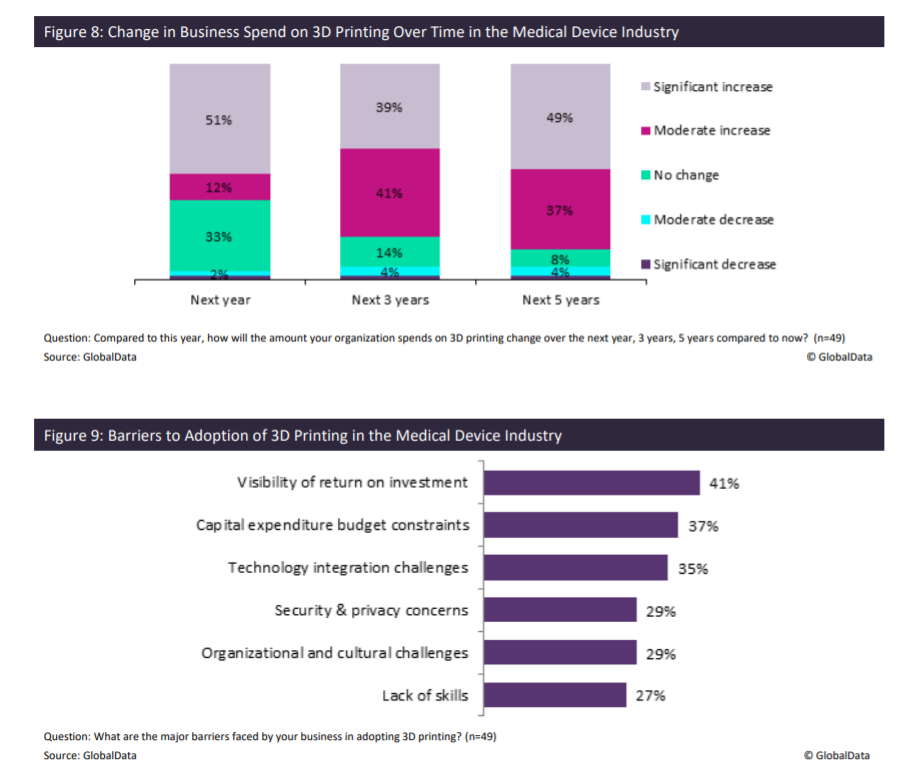

When asked about spending on 3D printing, most medical device companies expect to increase budgetary allocation to the technology over the next five years compared to current spending. This means that although some companies may harbour doubts over the nature of the disruption to come, they are still planning to increase investments into the trend.

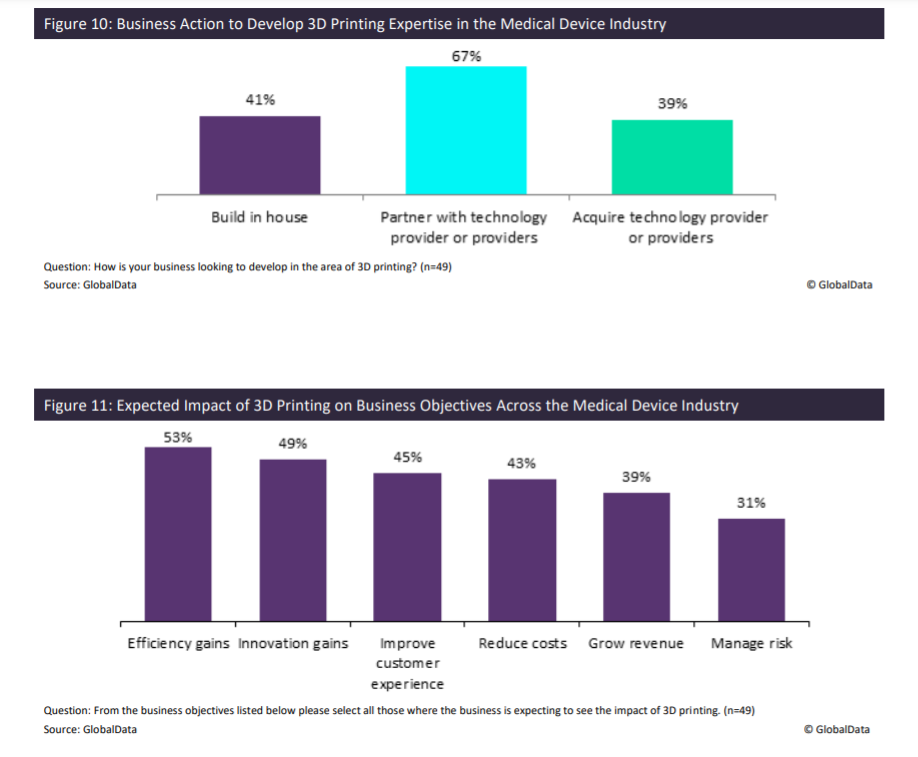

Two-fifths of companies surveyed see issues with the visibility of return on investment (ROI) as one of the barriers to adopting 3D printing. Concerns for CapEx budget constraints, technology integration challenges, and lack of skills were also highlighted as barriers.

As ROI and lack of in-house skills are cause for concern for respondents, the majority of companies (67%) were foregoing developing in-house acumen for partnerships with established 3D printing technology providers.

When asked what business objectives these companies are seeking to accomplish from investments in 3D printing technology, most respondents expect to be rewarded by efficiency (53%) and innovation gains (49%).