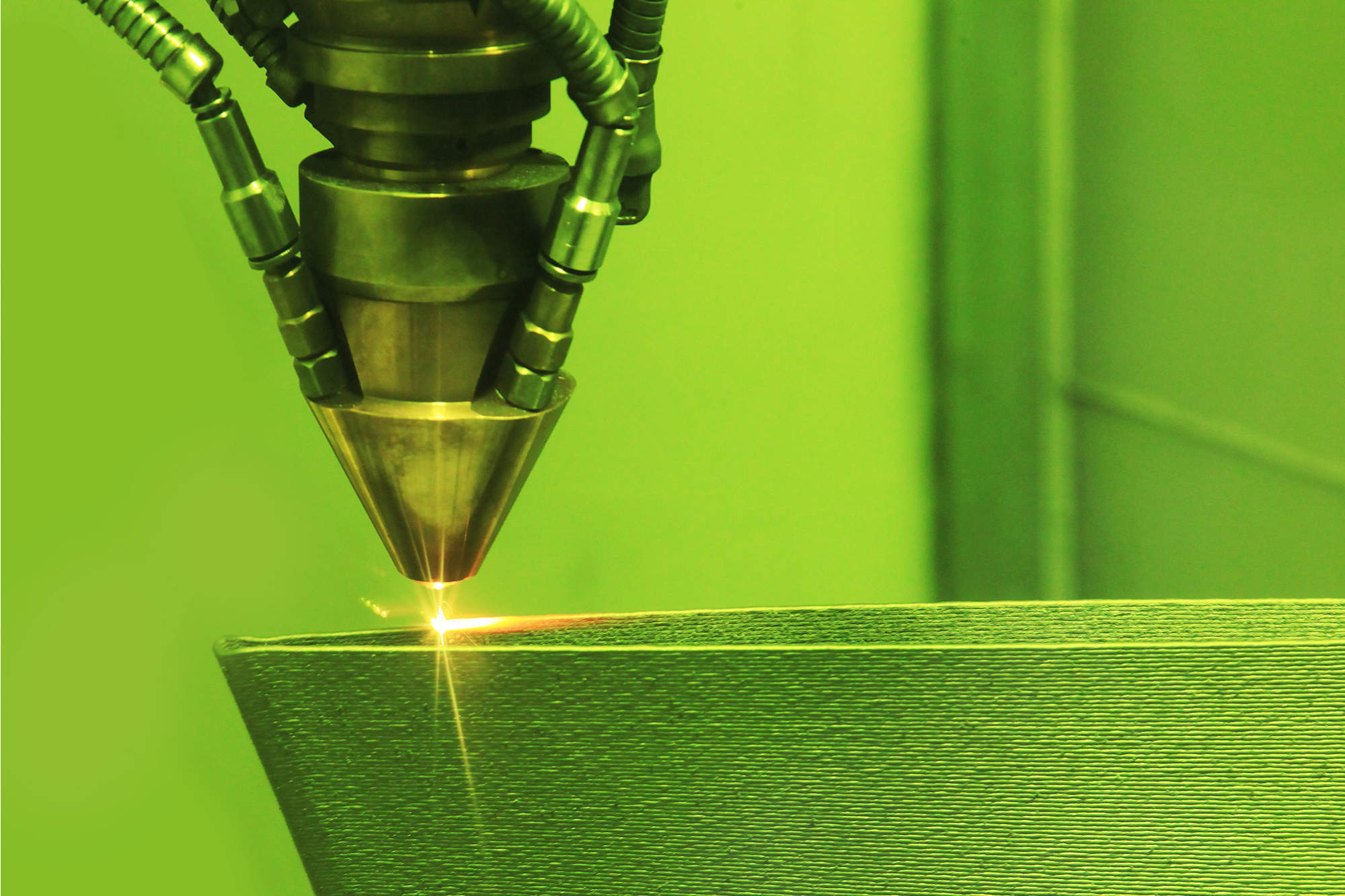

SPEE3D, an Australian supplier of metal-based additive manufacturing technology, has developed a way to 3D print anti-microbial copper proven to kill the Covid-19 virus.

Copper has natural antimicrobial properties, and has been shown to significantly reduce levels of MRSA, e-coli and influenza.

During the current Covid-19 pandemic, many organisations and individuals with access to 3D printers are deploying the technology to help medical professionals. For example, HP has developed a 3D printed nasopharyngeal test swabs, facemasks and ventilator components.

SPEE3D has modified its existing 3D printers so that existing metal parts can be coated with copper, known as ACTIVAT3D copper. The copper surface has been proven to significantly lower levels of SARS-CoV-2, the virus that causes COVID-19, on contact in just two hours.

According to SPEE3D, 3D printing copper parts from scratch can be difficult and time-consuming. Therefore, 3D printing technology to print copper surfaces to coat other items is faster and more affordable.

ACTIVAT3D copper has been tested by 360Biolabs. The tests showed that 96% of the virus was killed in two hours and 99.2% of the virus killed in 5 hours. Stainless steel, in comparison, showed no reduction in the virus levels.

Using 3D printing to combat the coronavirus

SPEE3D hopes that the material can be applied to items such as door handles, rails and touch plates in hospitals, schools and other public places instead of stainless steel or plastic, which SARS-CoV-2 can survive on for up to three days.

SPEE3D CEO Byron Kennedy said:

“The lab results show ACTIVAT3D copper surfaces behave much better than traditional stainless, which may offer a promising solution to a global problem. The technology can be used globally addressing local requirements, be they in hospitals, schools, on ships or shopping centres.”

SPEE3D sent the digital 3D printing files to participating partners around the globe, allowing newly-coated parts to be installed in buildings in the USA, Asia and Australia, reducing the chance these surfaces being contaminated with Covid-19.

Assistant director of digital design and additive manufacturing at the University of Delaware, Larry Holmes, said:

“Scientists and engineers at the University of Delaware were honoured to be part of this global research collaboration. We recognized the importance of developing simple, yet highly impactful, solutions that have been proven effective on COVID-19. Recognizing supply chain shortfalls over the last couple of months, it was clear to this team that fabrication speed was a priority. Using this technology, we are able to rapidly transition safe options for high-touch surfaces.”

Read more: Coronavirus case studies: How Whitgift School is manufacturing hospital visors.